| Availability: | |

|---|---|

| Quantity: | |

COLO-Line

COLO

This is a semi-automatic powder coating line. Compared with a fully automatic powder coating line, it can increase the powder coating products output while saving investment costs. The powder coating process is automaticall and it is equipped with a large cyclone recovery system, which is convenient for color change. The oven is equipped with a trolley. It is necessary to manually hang the sprayed products on the trolley and push it into the oven to bake for about 15 minutes. This type of line is idea for low budget and limist factory space.

The automatic powder coating booth equipment is a key part of high efficiency powder coating line system.

It is not only setup for simple spraying but also comes with two step powder recovery system that is cyclone and after filter recovery units, to achieve fast color change and realize 98% powder recovery.

It is the most efficient solution for high powder coating output capacity and clean coating condition.

Mono Cyclone Separator

Overspray powders will be transfered to cyclone first. The mono-cyclone is the most powerful choice for overspray collection especially in high speed and high productivity powder coating line.

The cyclone equipment uses centrifugal force and gravity to separate particulates from air stream according to their relative density. Thus, the powders will be effectively collected and transferred to the recycling equipment.

Cartridge Filter Unit

The secondary stage recovery unit usually includes 9-16 pcs cartridge filters.

As there are also some ultrafine powder particulates with light gravity will not fall down to cyclone bottom, they will be transfered to filter cartridges for final collecting.

Thus vented air stream from the whole system is free of dust particulates, creating a clean working environment.

Self-cleaning Booth Floor

The booth floor is designed with air knives and mesh plates specially for self-cleaning.

The cleaning system is controlled by air blasts, which remove the powder accumulated on the booth floor and push it to the extraction and recovery system.

The booth floor always remains clean with just a minimum amount of powder, and increase powder coating recovery.

Cyclone Powder Coating Spray Booth Specifications

| Model | COLO-S-PP |

| Booth Type | Automatic Type |

| Operator dimensions | Width800 x Depth6000 x Height2000 mm |

| Weight | 4000kg |

| Power supply | Electric |

| Nominal power | 15kw |

| Voltage | 380V/220V. customized as local. |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 32pcs (325*900) |

| Filters hang type | Rotary Wing, help filter cleaning |

| Filter cleaning system | Pneumatic |

| Booth Material | Wall:PVC; Floor PVC & Stainless Steel |

| Cyclone Material | Stainless Steel |

| Warranty | 12 months |

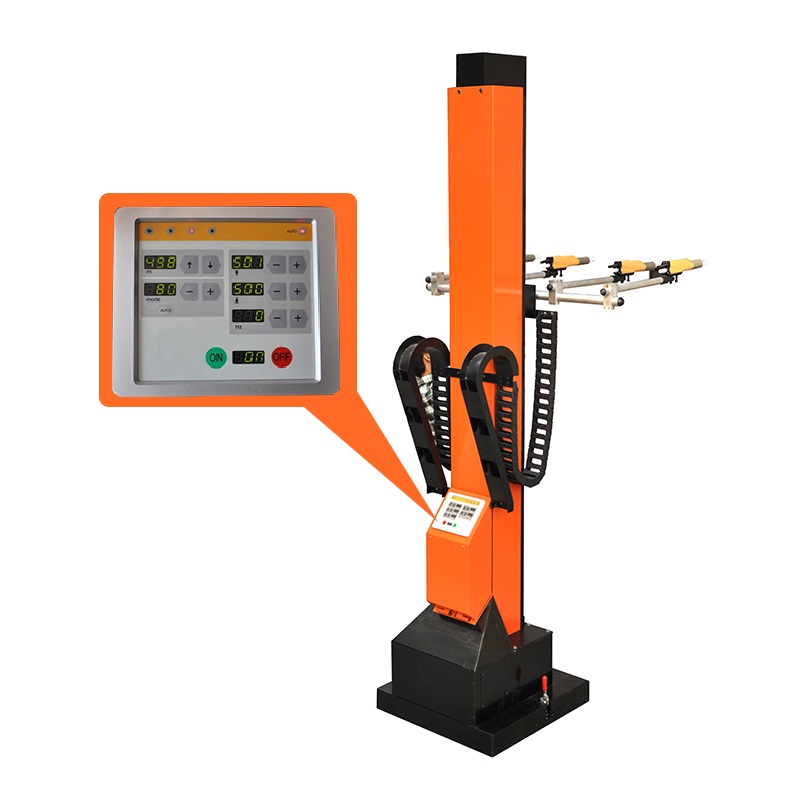

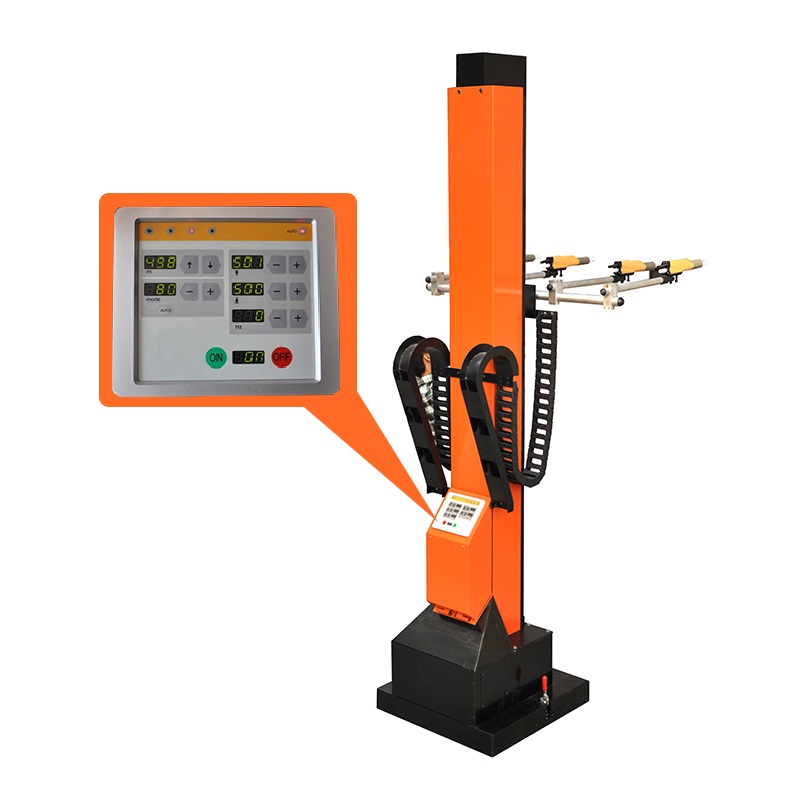

Automatic Powder Coating Reciprocating System

COLO-2000D reciprocator with COLO-800 automatic powder coating gun is a perfect set for automatic powder coating , the failure rate is low, frequent maintenance is not required, the service life is long, and the spraying quality is excellent.

COLO-2000D Reciprocator

1. Designed for consistent and uniform coating in automatic production line.

2. Allows to carry 2-12pcs spray gun, Sturdy construction could adapt to continual load everyday.

3. Movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

4. Driven by frequency motor, solid and maintenance free.

5. Working parameters are monitored on a user-friendly panel, which can memorize for 80 storable programs.

COLO-800D Control Cabinet

1. Multi controllers of COLO-800D automatic powder coating machine installed on a central cabinet, with compact design and simple operation.

2. Module design, can be tailored to customer's demands, allows to install Max. 24 control units.

3. Integrate with COLO painting reciprocators, part sensing system for highest efficiency.

4. Most suitable for high speed converised powder coating lines with consistent uniform film thickness.

COLO-800D Powder Gun Controller

1. Voltage can be flexibly adjusted from 0-100kv, the voltage and amperage values will be shown on the digital display for easy and accurate reading.

2.Just press the 3 one-touch intelligent buttons, coating mode can automatically and easily switched between flat-parts coating program, corner coating program and repeat coating program.

3.The 100kv automatic powder spray gun features high transfer efficiency and delivers smooth powder output, which optimizes powder utilization and application quality.

COLO-2000D Automatic Reciprocator Specifications

| Model | COLO-2000D |

| Power Supply | AC 220V/110V 50-60hz |

| Motor Power | 0.75 kW |

| Speed | 0-0.8m/s(0-50m/min) |

| Acceleration | 1 m/s |

| Max. Loading Capacity | 25 kg |

| Controller | Digital |

| Motor | Frequency Adjustable |

| Stroke | 2m |

| Qty of Spray Guns Loading | 2-12 pcs |

The COLO-6600 powder feed center is an integrated solution for all powder management needs to improve your automatic powder coating production. It is a very compact design and can be adapted to any system layout. It performs outstanding application features:

1. Highest cleaning efficiency due to automatic cleaning of all powder-carrying components(powder hose, pump, spray gun, etc)

2. High volume powder supplying thanks to big capacity fluidized hopper

3. Integrated control of all components of the powder coating line, includes powder center, spray booth, guns & reciprocators, curing oven.

4. Closed system for dustfree environment: directly connected with automatic booth recovery, avoids any powder spillover

5. Automatic Recovery and sieving, automatic recycling of overspray powders and mixing with fresh powder for maximum utilization of powder materials.

COLO-6600 Powder Feed Center Specifications

| Power Supply | AC 220V/110V 50Hz-60Hz (as required) |

| Overall Dimension | 1350*1940*900mm |

| Power Hopper Size | 550*550*550mm |

| Sieve Frame Size | φ400mm |

| Standard Mesh Size | 80 mesh (on request) |

| Air-in Pressure | 6-8bar |

| Recommended Air Compressor HP | 20kw(30HP) |

| Air Consumption | About 300 m³/h standard |

| Ambient | 5-40 ℃ |

COLO-5219 Powder Coating Oven with Trolley

1. Deigned with trolley with racking system, the trolley can design according to your items.

2. Completely new 100mm thickness rock wool board is perfectly to keep the temperature inside of oven which is very important.

3. It's a convection oven with indirect heating type,use heating exchange(stainless steel),more clean heat air and long life span.

4. PLC control system to operate the oven heating performance easily and precisely.

5. COLO powder coating ovens are designed to safely and efficiently cure previously applied powder coating media.

COLO-5219 Powder Coating Oven Specifications

| Model | COLO-5219 |

| Worksize Dimensions | Width1800 * Height1800 * Depth5000 mm |

| Overall Dimensions | Width2100 * Height2200 * Depth5200 mm |

| Power Supply | LPG / Gas / Diesel |

| Voltage/Frequency | 380V/220V (50-60Hz) |

| Warm-up Time | 15-30 min. (180° C) |

| Temperature Stability | < ± 3.0-6°C |

| Temperature | Max. 250° C |

| Transport System | Two trolleys |

| Burner | Italy Riello, 10,0000cal |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Ventilation Performance | 8288-16576m3/h |

| Motor Power | 7.5kW |

| Warranty | 12 months |

Why Choose COLO Powder Coating Lines?

We manufacture efficient powder coating line to meet the various requirements of our customers. We make sure to use the latest technology and have been praised by customers from all over the world. We believe that our quality will bring you a good shopping experience.

Our products are durable, easy to install, easy to clean and low cost. Our powder coatings are quality approved materials purchased from market leading suppliers and these products are checked for various quality parameters. If you have any needs, you can also let us know, we can customize it according to your requirements.

This is a semi-automatic powder coating line. Compared with a fully automatic powder coating line, it can increase the powder coating products output while saving investment costs. The powder coating process is automaticall and it is equipped with a large cyclone recovery system, which is convenient for color change. The oven is equipped with a trolley. It is necessary to manually hang the sprayed products on the trolley and push it into the oven to bake for about 15 minutes. This type of line is idea for low budget and limist factory space.

The automatic powder coating booth equipment is a key part of high efficiency powder coating line system.

It is not only setup for simple spraying but also comes with two step powder recovery system that is cyclone and after filter recovery units, to achieve fast color change and realize 98% powder recovery.

It is the most efficient solution for high powder coating output capacity and clean coating condition.

Mono Cyclone Separator

Overspray powders will be transfered to cyclone first. The mono-cyclone is the most powerful choice for overspray collection especially in high speed and high productivity powder coating line.

The cyclone equipment uses centrifugal force and gravity to separate particulates from air stream according to their relative density. Thus, the powders will be effectively collected and transferred to the recycling equipment.

Cartridge Filter Unit

The secondary stage recovery unit usually includes 9-16 pcs cartridge filters.

As there are also some ultrafine powder particulates with light gravity will not fall down to cyclone bottom, they will be transfered to filter cartridges for final collecting.

Thus vented air stream from the whole system is free of dust particulates, creating a clean working environment.

Self-cleaning Booth Floor

The booth floor is designed with air knives and mesh plates specially for self-cleaning.

The cleaning system is controlled by air blasts, which remove the powder accumulated on the booth floor and push it to the extraction and recovery system.

The booth floor always remains clean with just a minimum amount of powder, and increase powder coating recovery.

Cyclone Powder Coating Spray Booth Specifications

| Model | COLO-S-PP |

| Booth Type | Automatic Type |

| Operator dimensions | Width800 x Depth6000 x Height2000 mm |

| Weight | 4000kg |

| Power supply | Electric |

| Nominal power | 15kw |

| Voltage | 380V/220V. customized as local. |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 32pcs (325*900) |

| Filters hang type | Rotary Wing, help filter cleaning |

| Filter cleaning system | Pneumatic |

| Booth Material | Wall:PVC; Floor PVC & Stainless Steel |

| Cyclone Material | Stainless Steel |

| Warranty | 12 months |

Automatic Powder Coating Reciprocating System

COLO-2000D reciprocator with COLO-800 automatic powder coating gun is a perfect set for automatic powder coating , the failure rate is low, frequent maintenance is not required, the service life is long, and the spraying quality is excellent.

COLO-2000D Reciprocator

1. Designed for consistent and uniform coating in automatic production line.

2. Allows to carry 2-12pcs spray gun, Sturdy construction could adapt to continual load everyday.

3. Movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

4. Driven by frequency motor, solid and maintenance free.

5. Working parameters are monitored on a user-friendly panel, which can memorize for 80 storable programs.

COLO-800D Control Cabinet

1. Multi controllers of COLO-800D automatic powder coating machine installed on a central cabinet, with compact design and simple operation.

2. Module design, can be tailored to customer's demands, allows to install Max. 24 control units.

3. Integrate with COLO painting reciprocators, part sensing system for highest efficiency.

4. Most suitable for high speed converised powder coating lines with consistent uniform film thickness.

COLO-800D Powder Gun Controller

1. Voltage can be flexibly adjusted from 0-100kv, the voltage and amperage values will be shown on the digital display for easy and accurate reading.

2.Just press the 3 one-touch intelligent buttons, coating mode can automatically and easily switched between flat-parts coating program, corner coating program and repeat coating program.

3.The 100kv automatic powder spray gun features high transfer efficiency and delivers smooth powder output, which optimizes powder utilization and application quality.

COLO-2000D Automatic Reciprocator Specifications

| Model | COLO-2000D |

| Power Supply | AC 220V/110V 50-60hz |

| Motor Power | 0.75 kW |

| Speed | 0-0.8m/s(0-50m/min) |

| Acceleration | 1 m/s |

| Max. Loading Capacity | 25 kg |

| Controller | Digital |

| Motor | Frequency Adjustable |

| Stroke | 2m |

| Qty of Spray Guns Loading | 2-12 pcs |

The COLO-6600 powder feed center is an integrated solution for all powder management needs to improve your automatic powder coating production. It is a very compact design and can be adapted to any system layout. It performs outstanding application features:

1. Highest cleaning efficiency due to automatic cleaning of all powder-carrying components(powder hose, pump, spray gun, etc)

2. High volume powder supplying thanks to big capacity fluidized hopper

3. Integrated control of all components of the powder coating line, includes powder center, spray booth, guns & reciprocators, curing oven.

4. Closed system for dustfree environment: directly connected with automatic booth recovery, avoids any powder spillover

5. Automatic Recovery and sieving, automatic recycling of overspray powders and mixing with fresh powder for maximum utilization of powder materials.

COLO-6600 Powder Feed Center Specifications

| Power Supply | AC 220V/110V 50Hz-60Hz (as required) |

| Overall Dimension | 1350*1940*900mm |

| Power Hopper Size | 550*550*550mm |

| Sieve Frame Size | φ400mm |

| Standard Mesh Size | 80 mesh (on request) |

| Air-in Pressure | 6-8bar |

| Recommended Air Compressor HP | 20kw(30HP) |

| Air Consumption | About 300 m³/h standard |

| Ambient | 5-40 ℃ |

COLO-5219 Powder Coating Oven with Trolley

1. Deigned with trolley with racking system, the trolley can design according to your items.

2. Completely new 100mm thickness rock wool board is perfectly to keep the temperature inside of oven which is very important.

3. It's a convection oven with indirect heating type,use heating exchange(stainless steel),more clean heat air and long life span.

4. PLC control system to operate the oven heating performance easily and precisely.

5. COLO powder coating ovens are designed to safely and efficiently cure previously applied powder coating media.

COLO-5219 Powder Coating Oven Specifications

| Model | COLO-5219 |

| Worksize Dimensions | Width1800 * Height1800 * Depth5000 mm |

| Overall Dimensions | Width2100 * Height2200 * Depth5200 mm |

| Power Supply | LPG / Gas / Diesel |

| Voltage/Frequency | 380V/220V (50-60Hz) |

| Warm-up Time | 15-30 min. (180° C) |

| Temperature Stability | < ± 3.0-6°C |

| Temperature | Max. 250° C |

| Transport System | Two trolleys |

| Burner | Italy Riello, 10,0000cal |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Ventilation Performance | 8288-16576m3/h |

| Motor Power | 7.5kW |

| Warranty | 12 months |

Why Choose COLO Powder Coating Lines?

We manufacture efficient powder coating line to meet the various requirements of our customers. We make sure to use the latest technology and have been praised by customers from all over the world. We believe that our quality will bring you a good shopping experience.

Our products are durable, easy to install, easy to clean and low cost. Our powder coatings are quality approved materials purchased from market leading suppliers and these products are checked for various quality parameters. If you have any needs, you can also let us know, we can customize it according to your requirements.